- Producing wooden storage boxes is a fine art in itself,

- and here at our works in Boston Lincs, we not only have purpose

- built machinery for producing the boxes, but very accurate and precise

- machines for processing the raw materials into box components.

Facilisi

Voco

Vocoproprius

Facilisivoco

Quis nimis

Quis nimis

2.

Selected timber is

profile planed and then

cut to a tolerance of

+ /- 0.5mm, before

being allocated to a

specific order.

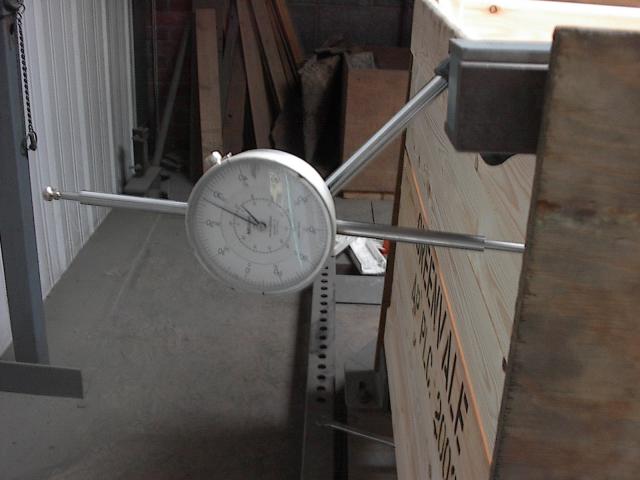

1.

Upon specification

details being confirmed,

the design is checked

and verified, and when

required, a box is

tested on our " In

House " test rig to

confirm requirements

before production.

6.

The end customer

puts the product

into rigorous use.

5.

Transport of the

finished products is

delivered by our own

vehicle where possibe

External hauliers

are carefully sourced

to help out when

required.

4.

The final assembly of

the boxes is semi

automatic and the

machinery ensures a

consistent reliable

sequence of quality

nailing paterns ensuring a

nice tight fit to all of the

components.

3.

Precut timber is loaded

into the machines, and

these box sections are

automatically nailed

using zinc plated nails,

prior to final assembly.

Computerised machines

ensure a consistent

quality.

Pearson

Packages

Ltd.

Pearson Packages Ltd, Benington Rd, Butterwick, BOSTON, Lincs PE22 0EX Tel. 01205 760430 Company Registration No. 1359866 Website by Andy Pearson

Fax. 01205 761080 Pearson Packages Ltd